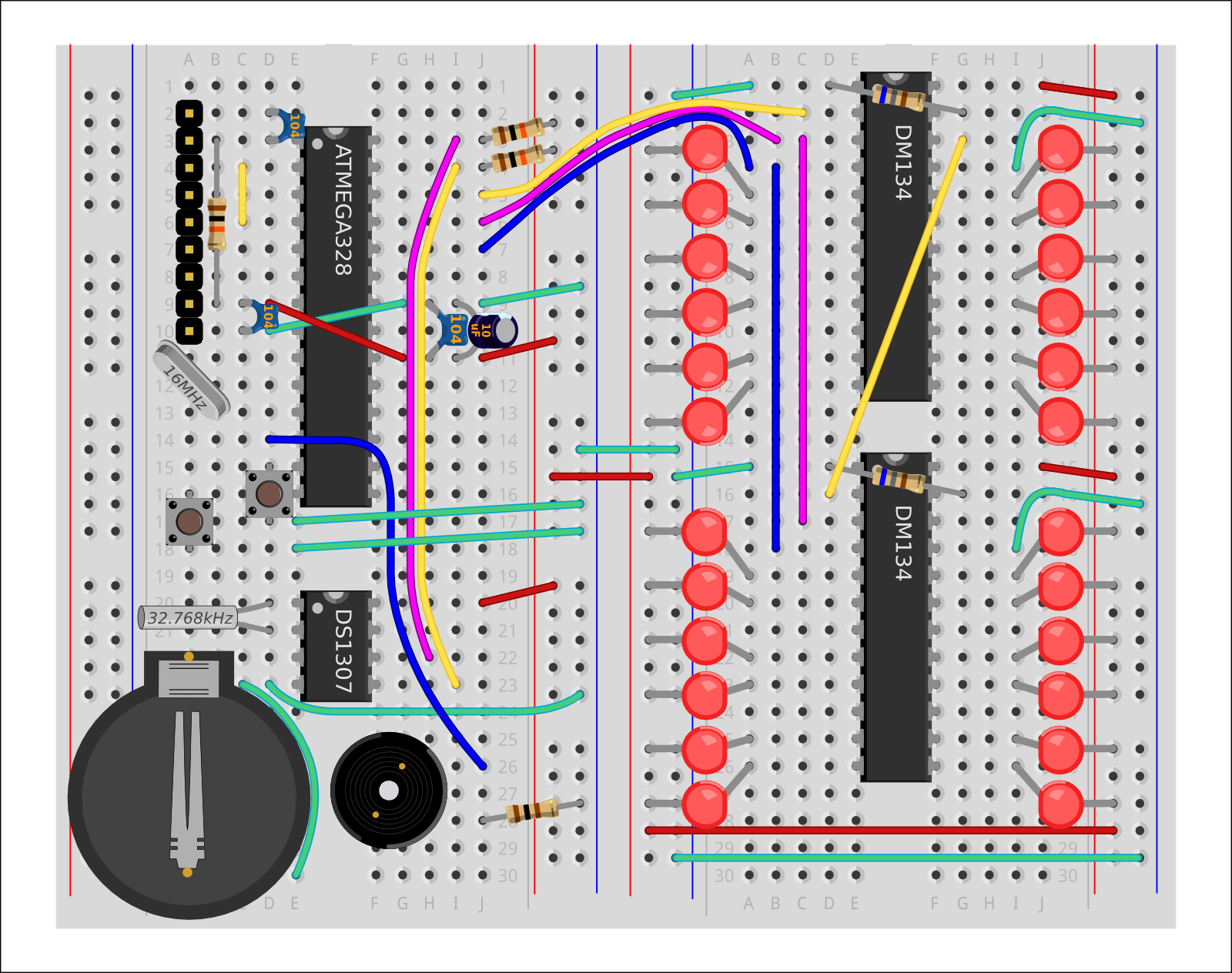

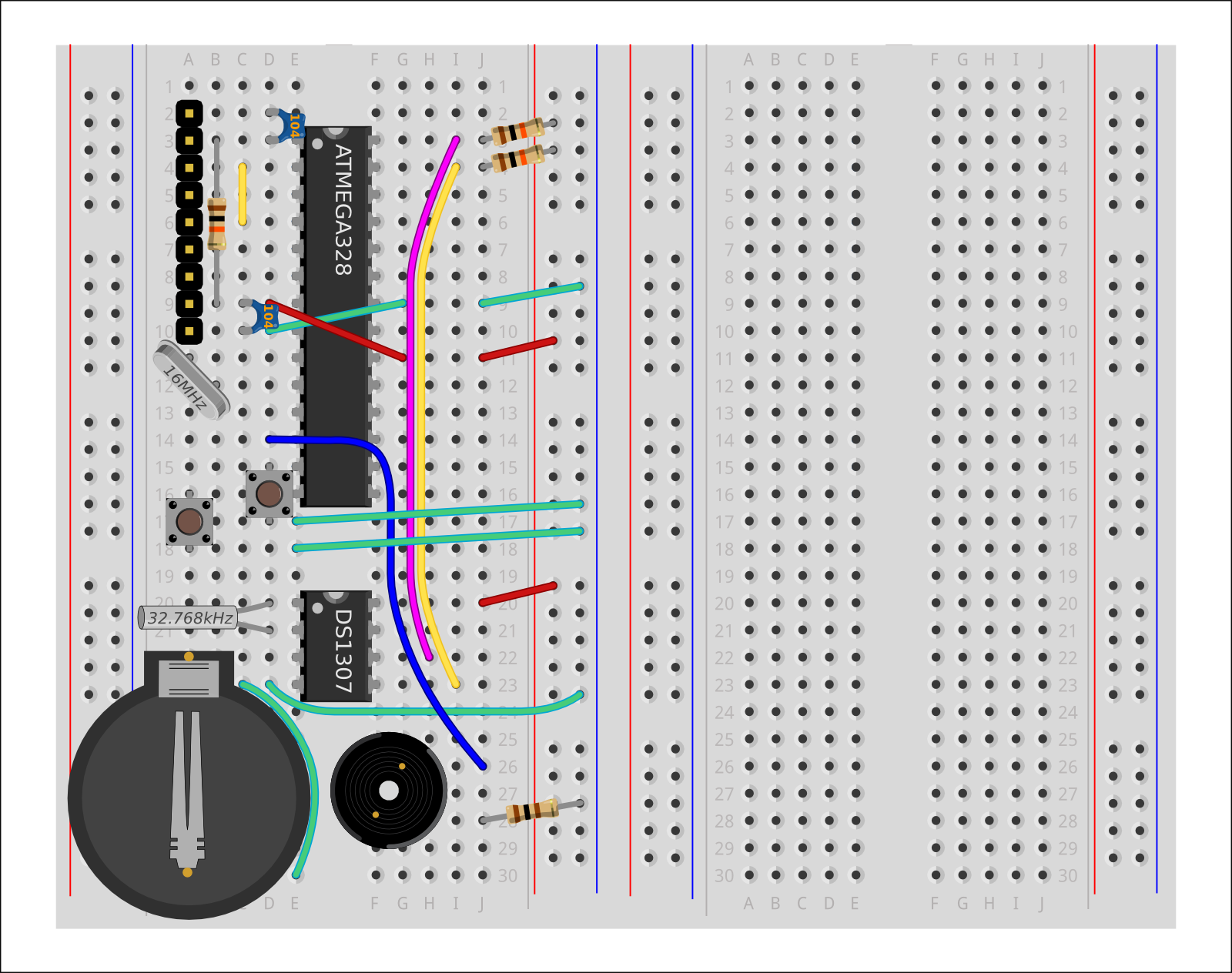

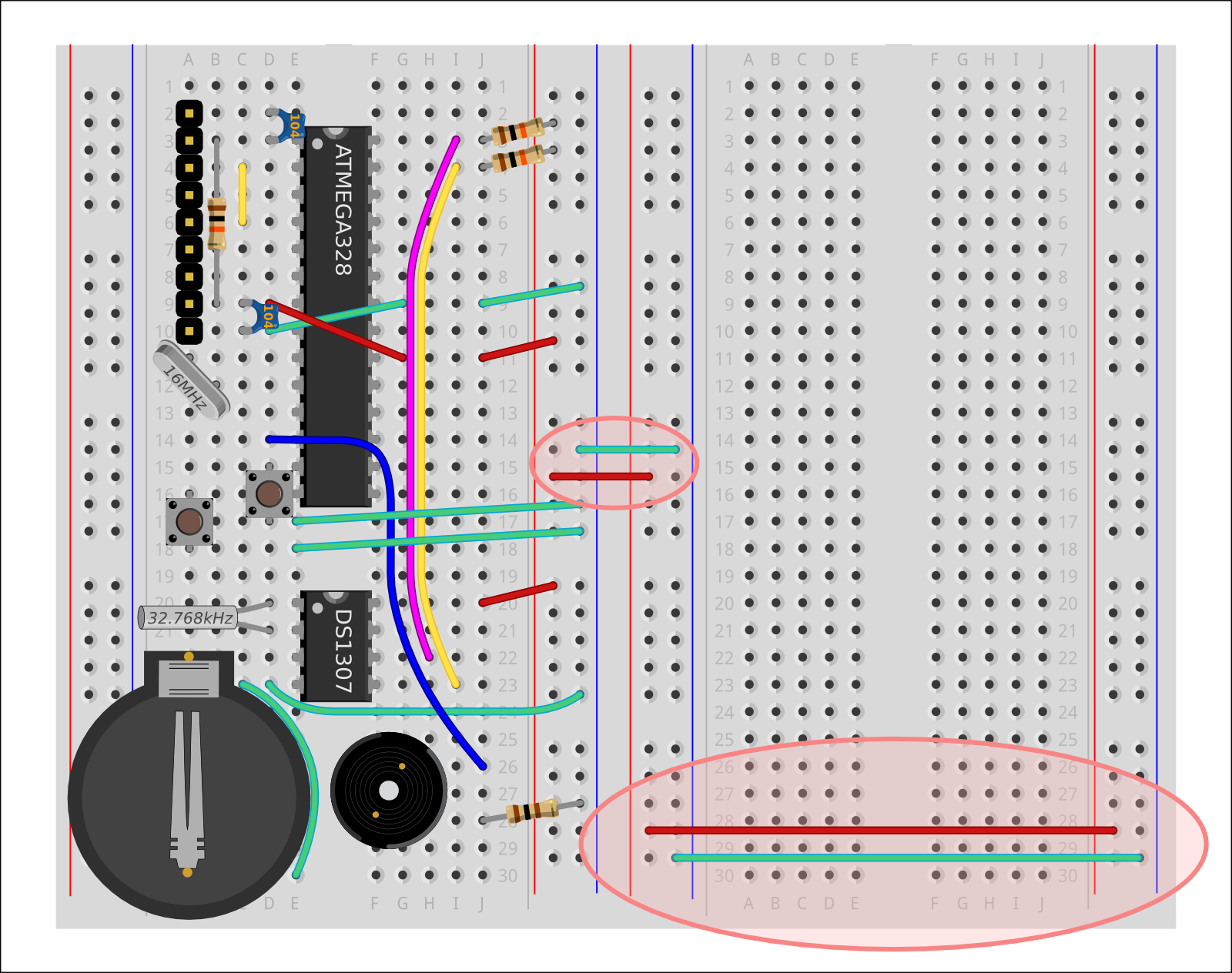

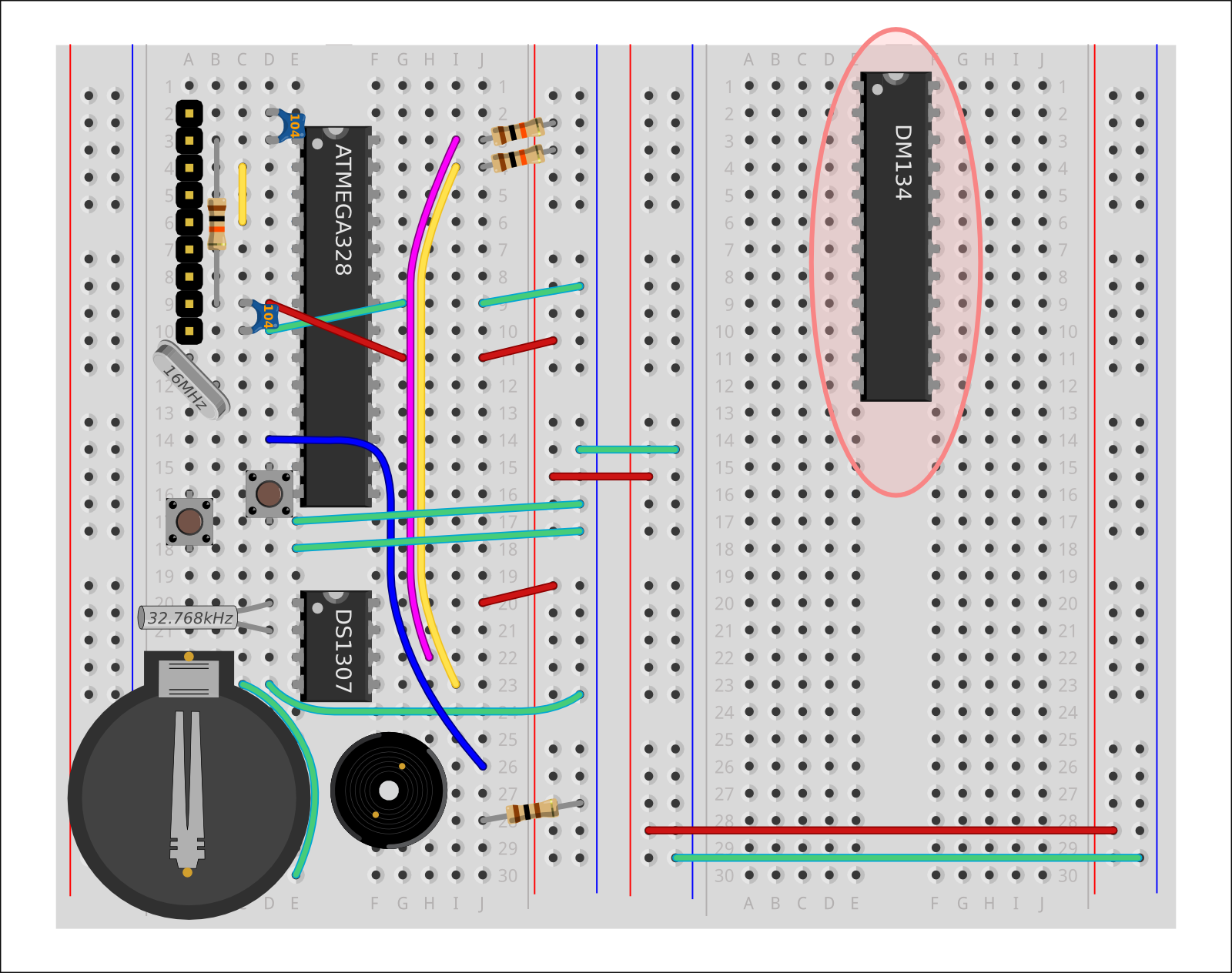

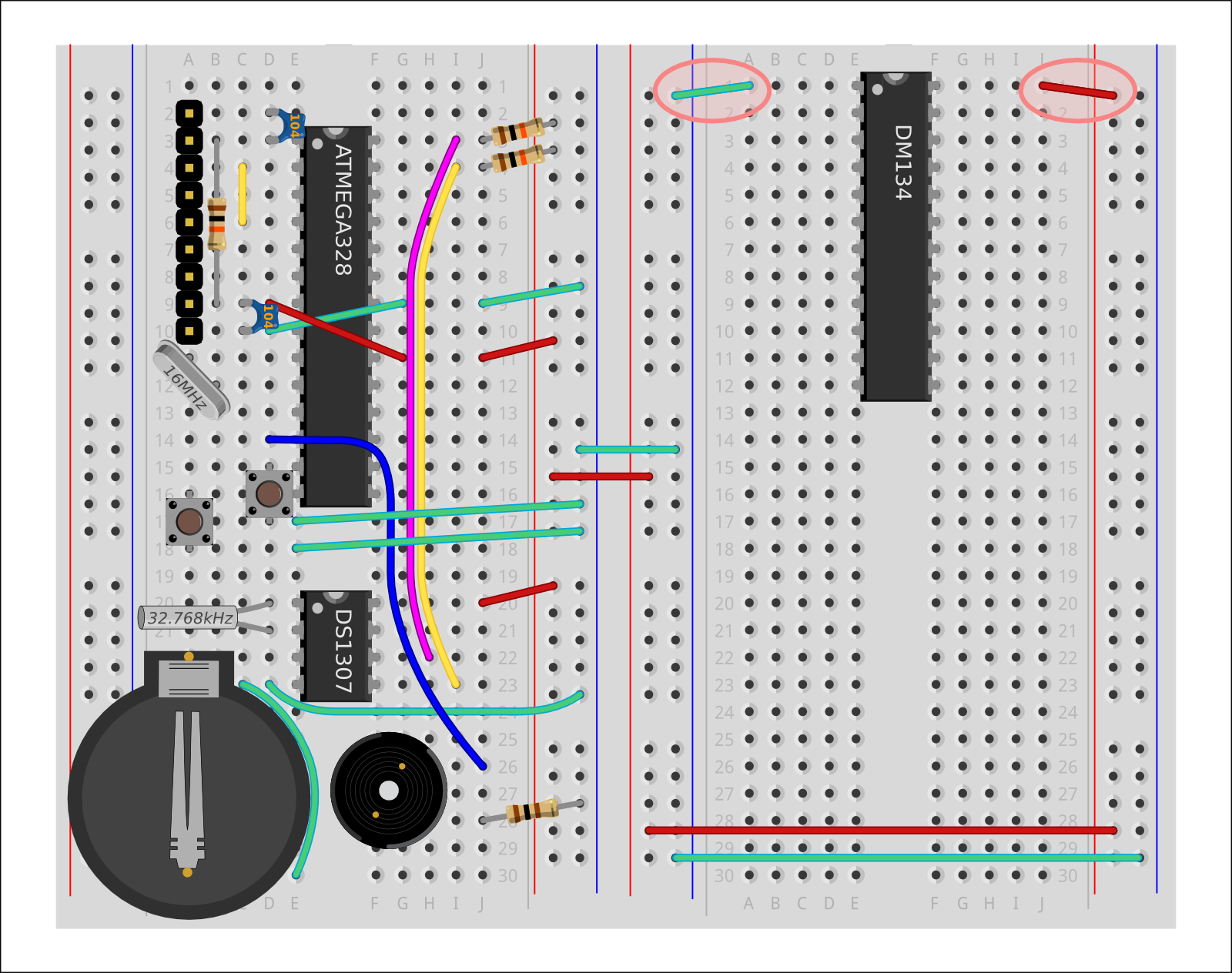

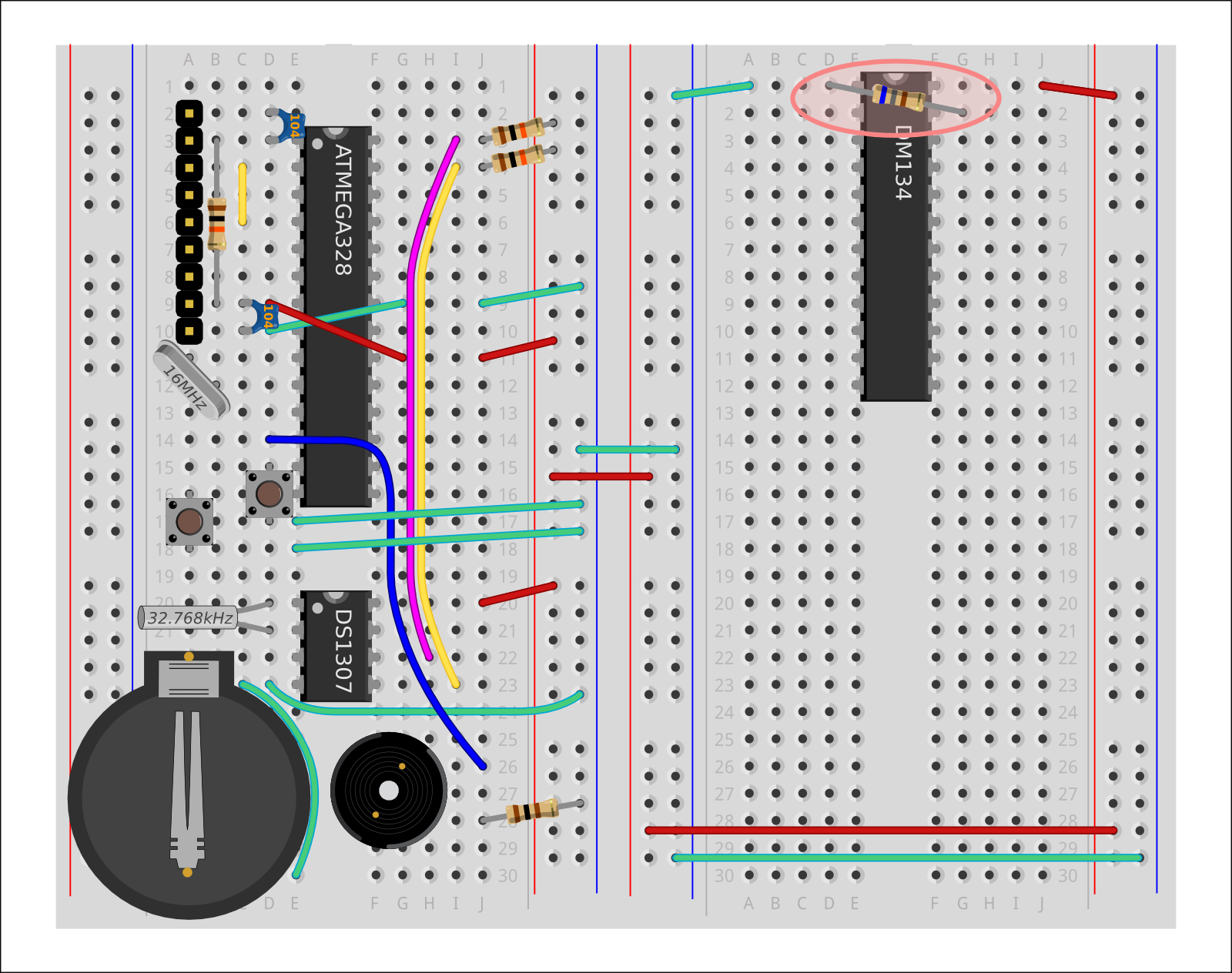

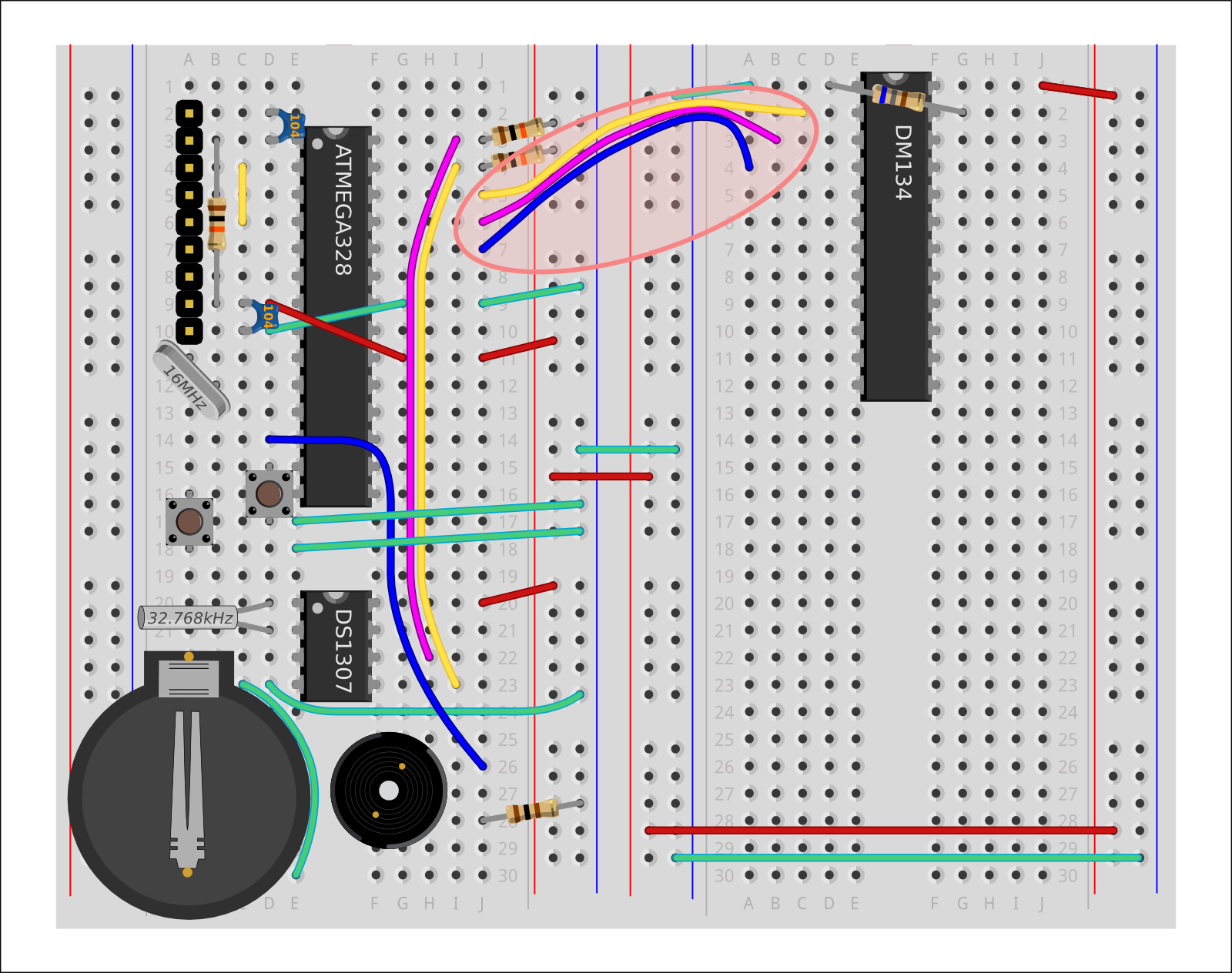

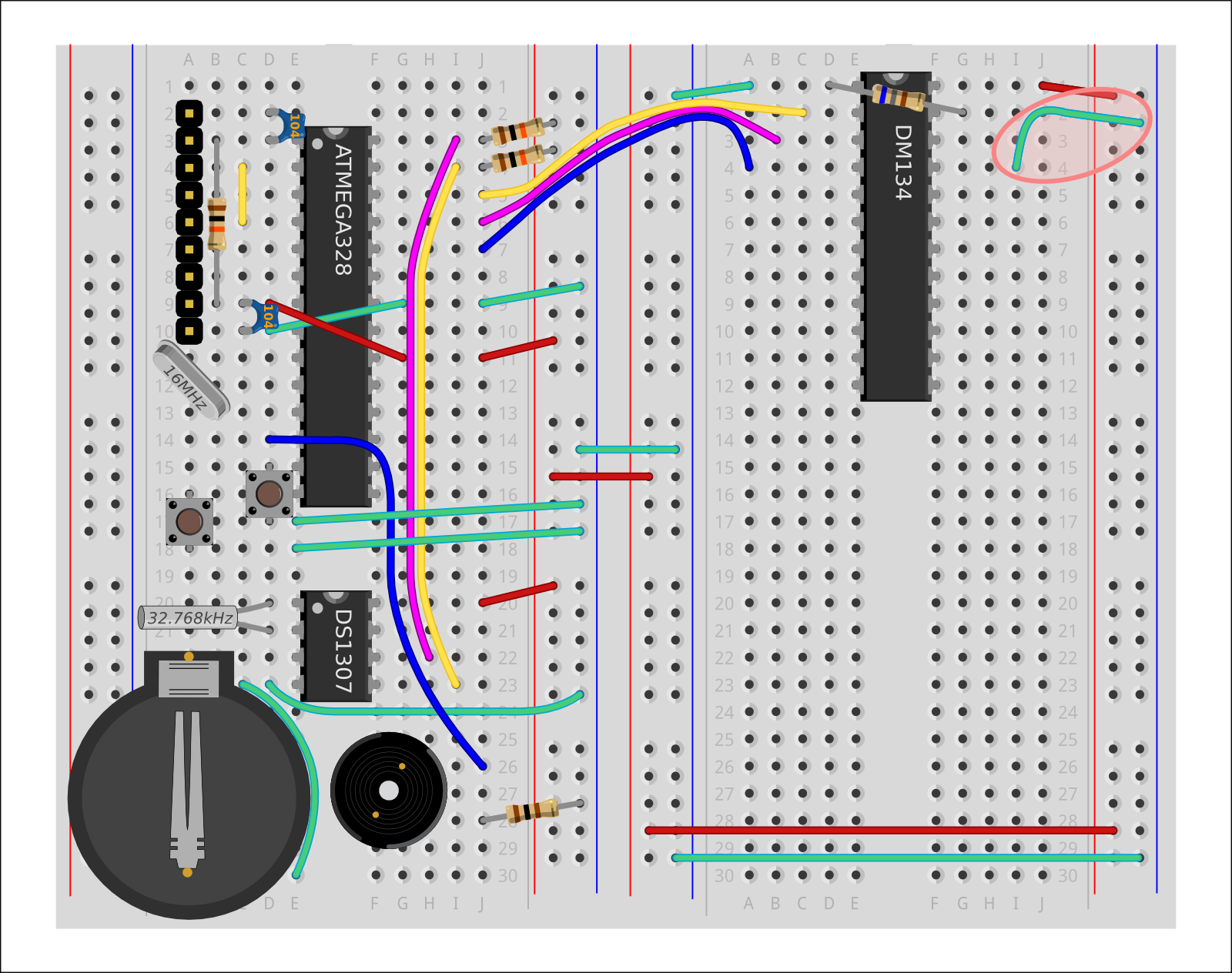

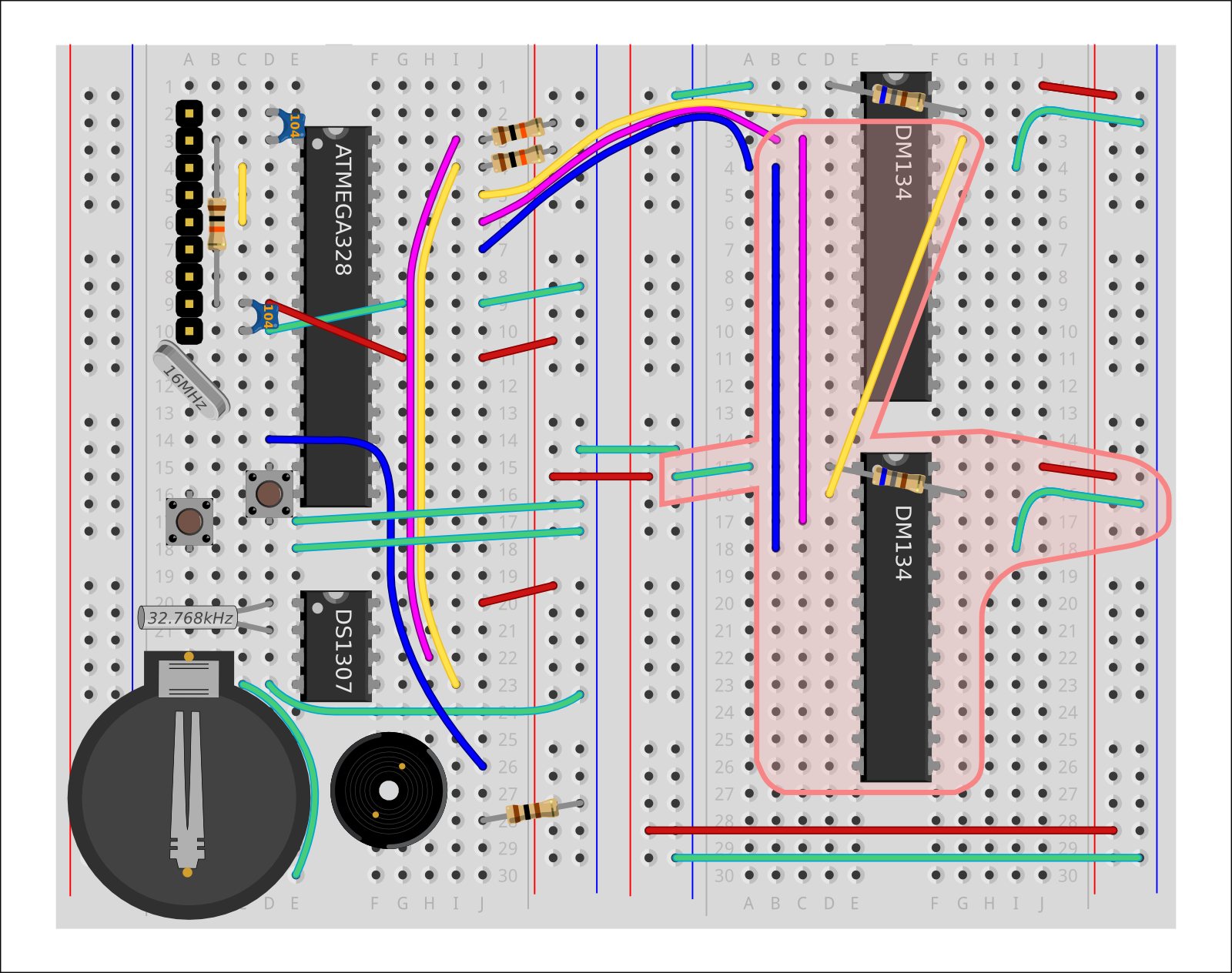

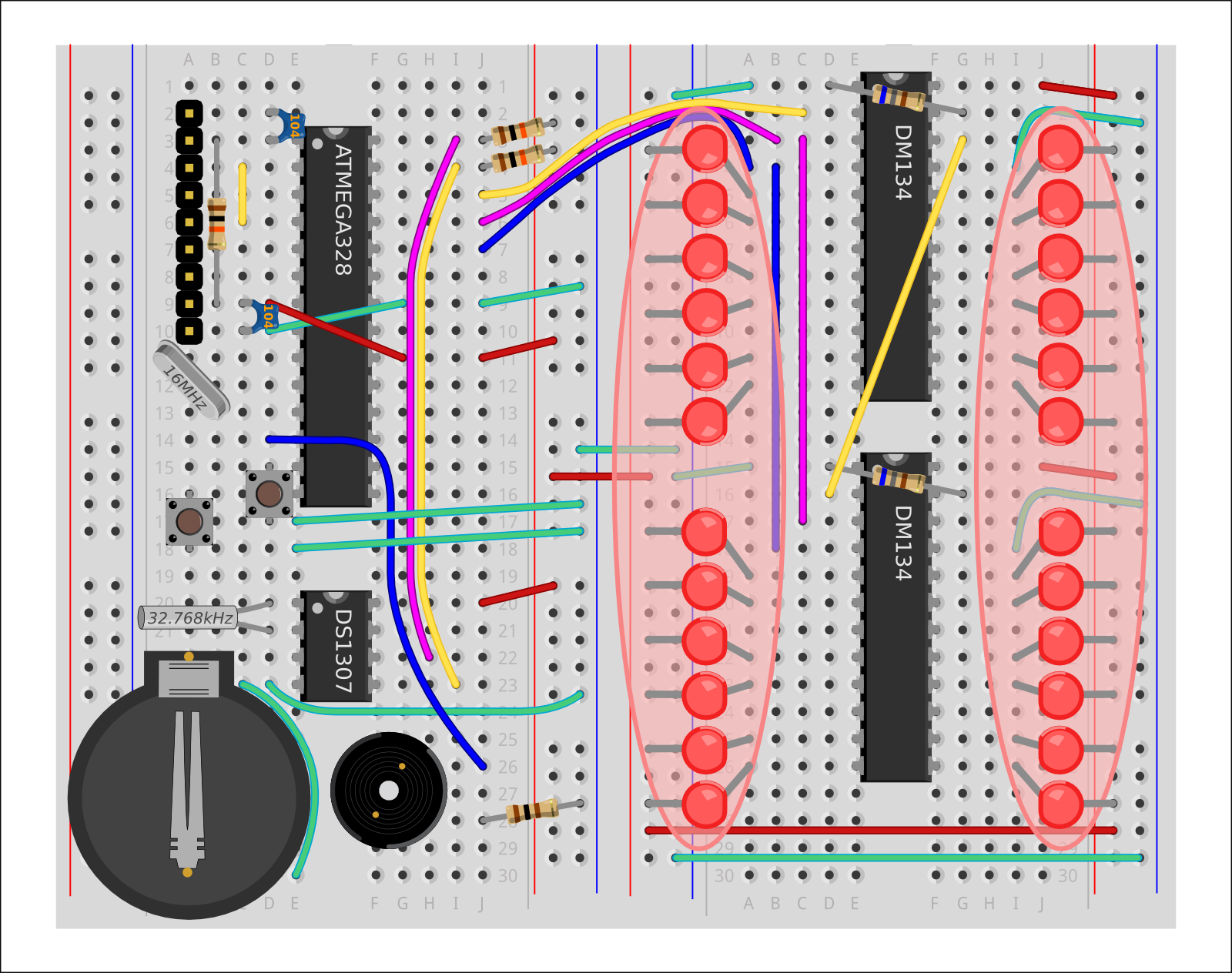

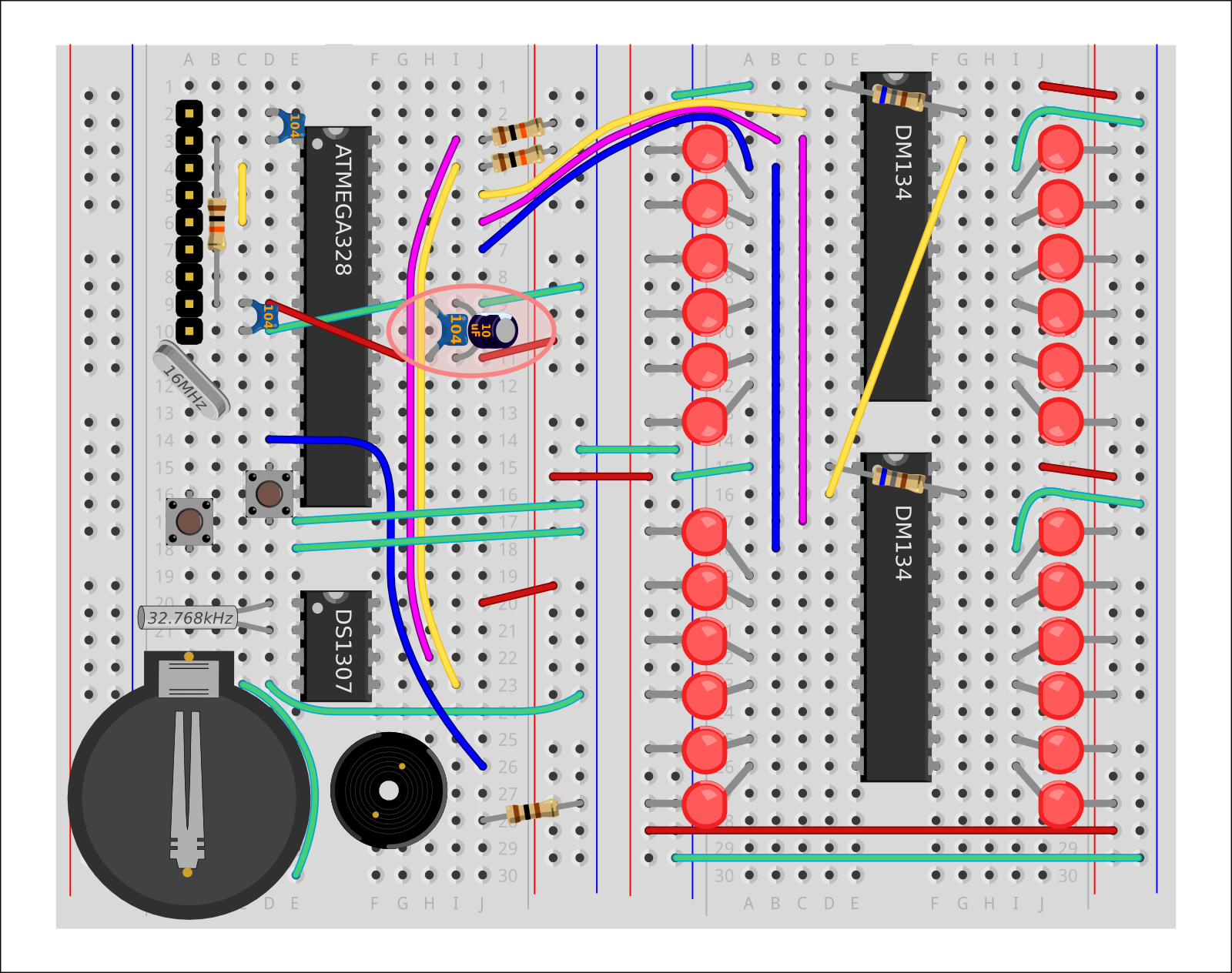

This guide provides details for learners to wire, program and configure their first @ShrimpingIt digital clock project. It incorporates two LED driver chips which control ultrabright LEDs in a layout which can be programmed as a Word Clock or a Unary Clock. For general orientation, see the LED Clock project page. The completed build should replicate the image shown.

For convenience, pre-bagged kits are available to order from @ShrimpingIt online. If you do not wish to buy from us, information is provided for you to source commodity parts direct from electronics wholesalers.